How to illuminate the metallographic microscope in Shanghai

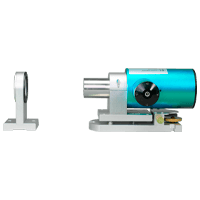

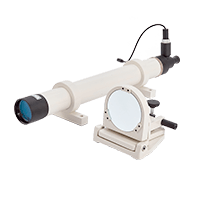

Metallographic microscope is an important optical instrument for analyzing the metallographic structure of metal materials. Metallography mainly refers to the branch of materials science that analyzes, studies and characterizes the microstructure, low magnification structure and fracture structure of materials by means of optical (metallographic) microscopes and stereo microscopes, etc. Quantitative characterization also includes necessary sample preparation, preparation and sampling. It mainly reflects and characterizes the phase and organizational composition, grains (including possible sub-crystals), non-metallic inclusions, and even the number, morphology, size, distribution, orientation, and spatial arrangement of some crystal defects that constitute the material. status, etc. Metallographic microscopes have special illumination systems. Most of its illumination light sources are installed on the side or rear of the mirror body. In order to achieve the purpose of allowing light to enter the objective lens and then enter the eyepiece, it is necessary to install a reflector (plane mirror or prism) at the intersection of the two optical axes to make the light Vertical steering, if the light source is designed at the bottom of the metallographic microscope, the illuminating beam directly passes through the objective lens to the surface of the metallographic sample, and is reflected by the surface of the sample to the objective lens for imaging, and finally the reflector is used for vertical steering. The role of vertical lighting, it is called “vertical illuminator”. Metallurgical microscopes use different ways of reflecting mirrors to turn the beam (or image), and the illumination methods include bright field and dark field illumination. 1. Bright field illumination Bright field illumination is a commonly used illumination method in metallographic microscopes. It relies on a vertical illuminator to emit light from the light source to the objective lens, and the objective lens then reflects the vertical or nearly vertical light on the grinding surface […]